traxxas-modifier said:

hi guys

my question is,

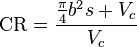

how is the Compression Ratio computed?

Quite simple actually. Compression ratio is the ratio of the cylinder's volume when the piston is at BDC divide by the volume when the piston at TDC. Let say the former volume is 100cc and the latter is 10cc. 100/10 equal to 10:1 compression ratio. You can calculate it by measuring everything, but the most accurate way is by performing liquid test.

The higher the compression ratio, meaning the AF mixture is compressed more and more power produced to crank. There are many factor limiting the compression ratio that you can have on your engine, one of it is the fuel being used. Racing fuel have higher octane rating, meaning you can have your engine with higher compression ratio, more than you can have when using pump fuel.

The picture that Mr. Rockies's provide not necessarily caused by high compression ratio setup. I believe the valve bent because it hit the piston head. The root cause might be inacurate measurement of the piston to valve clearance. Might also because of the valve spring failed? or the timing chain snap?

If you are going to have your bike's engine modified to high compression, i would recommend you to get a big valve head with 5-angle valve seat cut, like the one Mr Rockies is selling. That should provides adequate valve sealing. I'm hoping my explaination is clear enough. Cheers!